Real-time PPE Inspection at Unmanned LNG Stations

Gas and Oil company from Czech Republic builds LNG stations

Automated PPE inspections with Computer Vision

Problem

Neglection of safety rules

A Czech Gas and Oil company is building unmanned LNG stations. Due to the inherent risks of LNG, using proper PPE like Cryogenic Gloves is essential. However, many drivers weren't using them.

Reviewing security footage was tedious and on-site checks costly, so they needed a cost-effective way to detect non-compliant drivers.

Solution

Automated inspections with Computer Vision

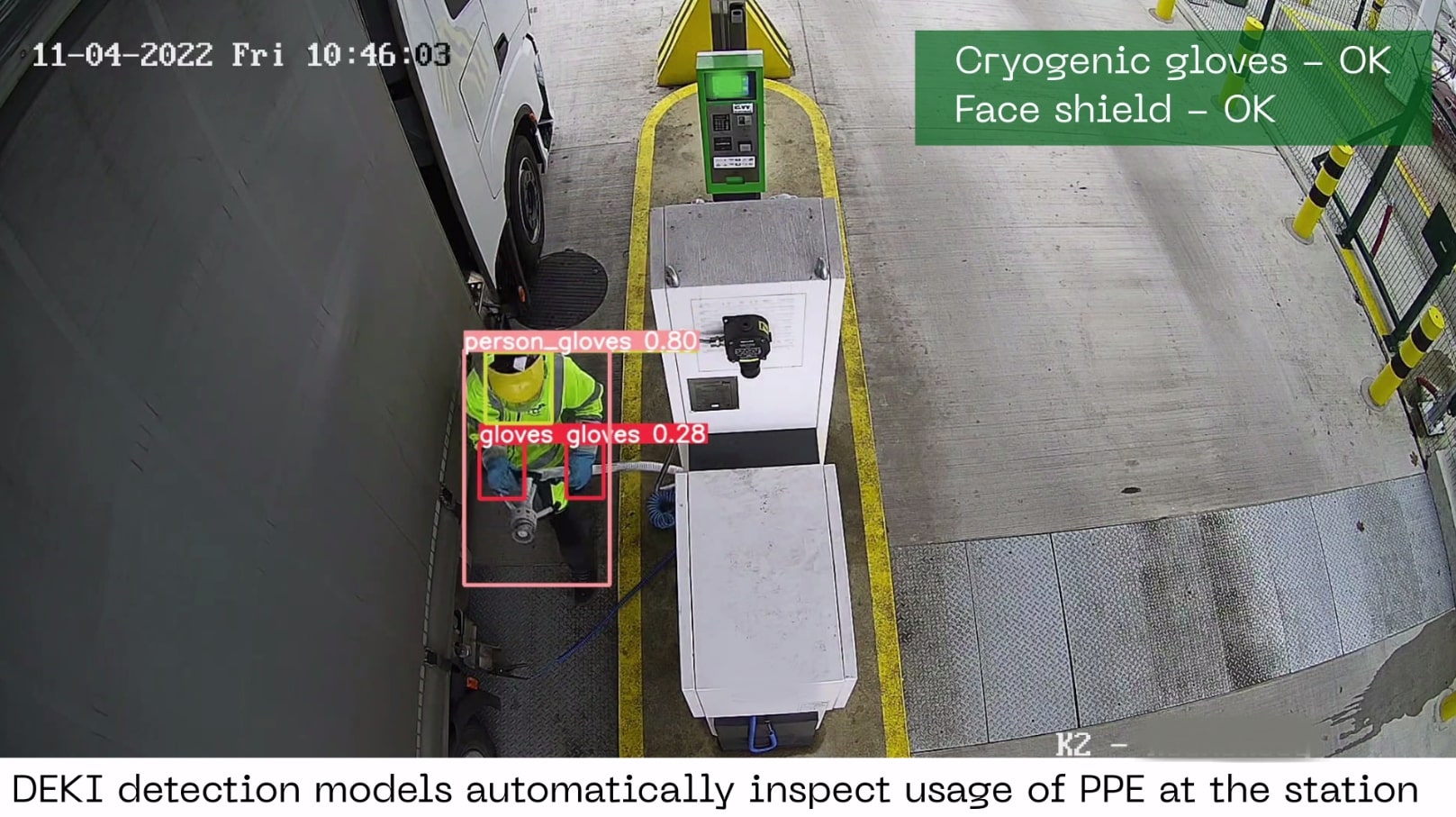

DEKI suggested using the station's existing security cameras (K1, K2, & K3) to detect Cryogenic Gloves a Face Shields via RTSP video streams. These streams were processed by detection models on an edge device for a proof of concept.

Results

Automated PPE inspection system

The system achieved 83% PPE detection and 82% license plate accuracy, exceeding the 80% benchmark. It offers 24/7 monitoring, enabling corrective actions for safety breaches. After the PoC's success, the client has decided to continue enhancing the system to provide proactive notifications to the drivers as well.

The Problem:

A Gas and Oil company from the Czech Republic is in the process of building several unmanned LNG stations. Since the tanking process for LNG is fundamentally unsafe, adherence to safety protocols, primarily wearing appropriate Personal Protective Equipment (PPE) like Cryogenic Gloves and face shields, is paramount. After inaugurating their first station, the company discovered a worrisome trend: many drivers were not using the appropriate PPE.

With the manual review of video recordings from the security cameras present being time-consuming and hiring personnel for on-site checks financially untenable, the company sought an innovative, cost-effective solution to detect those drivers that do not use appropriate PPE while at the station, endangering themselves and those around them.

Objective:

Automate PPE inspections at the LNG stations to ensure drivers' safety without the need for onsite personnel or tedious video reviews. Leverage the current infrastructure at the station to cut costs of equipment necessary for such a solution. Send all detected events into a portal where they can be viewed, reviewed, and exported for later use.

Solution by DEKI:

DEKI proposed a system that leverages the existing security cameras at the station. Three cameras were already in place: one monitoring the station's front (K1) and two overseeing the terminal where tanking occurred (K2 & K3). We could connect with the video streams from the cameras locally via RTSP and process them with our detection models deployed on a small edge device. The primary focus for this Proof of Concept (PoC) was the detection of Cryogenic Gloves and Face Shields.

Solution Workflow:

- If a person in this region is observed wearing the necessary PPE, the event is marked as "PPE SUCCESS," associated with the license plate, and transmitted to a centralized collector.

- If one or both PPE elements are missing, the event is recorded as "INCOMPLETE PPE," and similar data is sent to the collector.

The collector, built to client specifications and accessible via a web portal, aggregates all events. It logs event specifics, timestamps, license plate data, and snapshots for potential manual review. This entire process is designed to be cost-effective, leveraging existing infrastructure, and works without the need of internet connectivity to ensure clients data security.

Challenges & Solutions:

- False Events: Detection of personal vehicles mistaking the station for a standard gas station were addressed by refining the vehicle detection model to differentiate between personal vehicles and trucks.

- Multiple License Plates: Trucks often displayed multiple license plates, mainly as keepsakes. This skewed character extraction results. The issue was resolved by focusing detection solely on license plates positioned at the truck's base.

- PPE Detection: Differentiating between Cryogenic Gloves and regular gloves was challenging. Improving the dataset, adjusting model weights, and optimizing the algorithm enhanced accuracy. The transparent face shield also presented detection challenges, but iterative model adjustments ensured acceptable detection rates.

- License Plate Detection: Given the existing cameras' limitations and the 15-meter distance to vehicles, DEKI had to enhance the license plate detection algorithm for correct character extraction. Additionally we were given a list with license plate numbers of the customers at the station for result comparison which greatly improved the detection score.

Results and Next Steps:

The system demonstrated an 83% true positive rate for PPE detection and 82% accuracy for license plate identification, surpassing the client's 80% benchmark. This real-time 24/7 monitoring system serves as evidence if drivers repeatedly breach safety rules, facilitating corrective actions through their respective companies.

Encouraged by the PoC's success, the client decided to continue collaboration with DEKI. The roadmap includes system enhancements, improving detection accuracy, and integrating proactive audio warnings for drivers previously detected without PPE. Following these upgrades, the solution is slated for deployment at other existing and future LNG stations.

“Thank you for the excellent cooperation with DEKI. DEKI, though compact, is a modern, active, flexible, and highly efficient contractor for automation of PPE inspections with Computer Vision. I look forward to continuing in the same manner on other projects.”

Michna David

Senior WHS Specialist