What is Automated PPE Inspection?

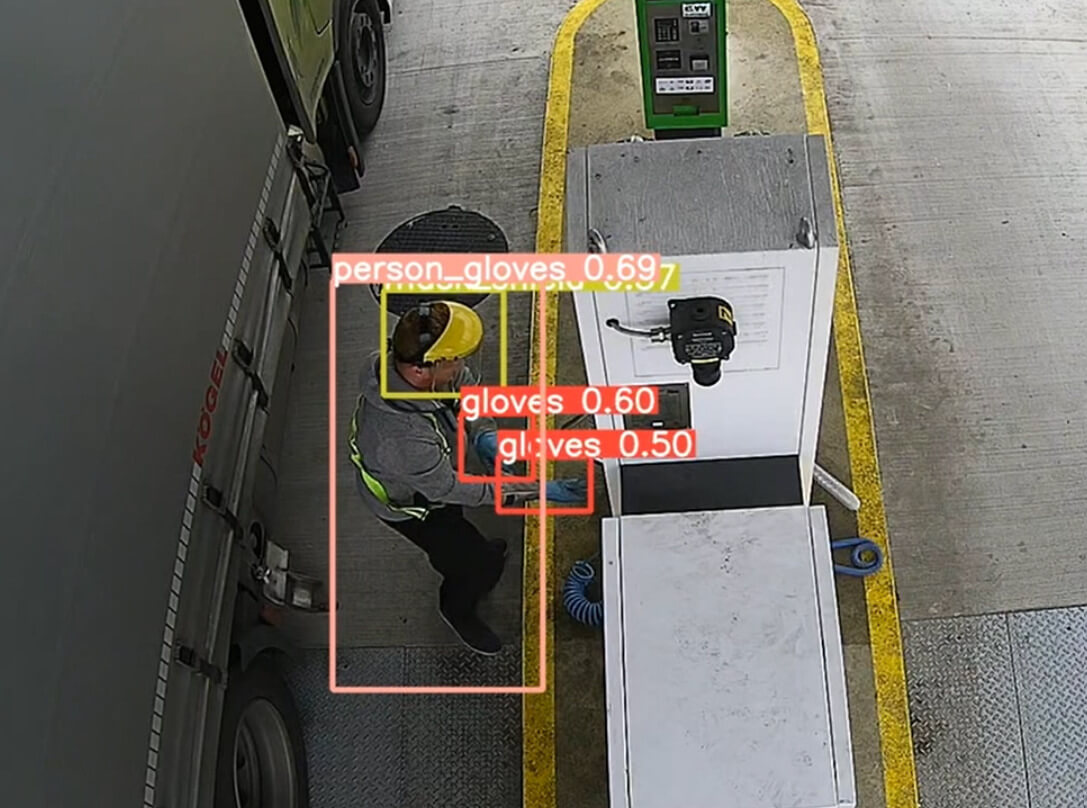

Computer Vision can be used to detect the presence of workers and equipment such as PPE (Personal Protective Equipment). Machine learning algorithms can accurately recognize objects at facilities and construction sites by analyzing real-time video streams from already installed IP camera surveillance systems. DEKI helps improve safety and productivity in manufacturing or construction, by detecting and monitoring PPE usage by helmet detection, eye protection detection, vest detection, and more.

24/7 With a High Accuracy

The automated equipment inspection works 24/7/356, is more consistent and generates more accurate results compared to the human inspectors.

Real-Time Notification

Get notified instantly any time there is a detected safety violation and follow up with an action: trigger audio announcements, stop machine operation to prevent injury and more.

Safety Report Creation

All of the data from detected events is stored locally on the premises and it can be used to create statistics and safety reports for upper management and insurance companies.

Key Features of PPE Detection

Real-time object detection for the inspection of PPE is an automated, scalable, and non-invasive solution to quickly improve workplace safety and efficiency.

Increased Efficiency

DEKI Computer vision System automates the PPE inspection process, allowing for faster and more efficient inspections. By using edge devices, inspections can be performed on-site without the need for an internet connection or cloud-based processing, further increasing efficiency.

Improved Accuracy

The DEKI Computer vision System is capable of detecting even small defects or issues with PPE that might be missed during manual inspections. This improves accuracy and ensures that any issues with PPE are detected and addressed promptly.

Access Control & Safety

Our license plate detection system ensures that only authorized vehicles access the facility, providing an essential layer of theft prevention and security. In emergencies, the system's vehicle log proves invaluable for swift emergency response. Additionally, our system seamlessly integrates with other security measures, such as CCTV, offering a holistic view of security events.

Cost Savings

By automating the PPE inspection process, the DEKI Computer vision System can reduce the need for manual inspections, freeing up resources and reducing labor costs. Additionally, by detecting issues with PPE early, the system can help to prevent costly accidents or equipment failures.

Enhanced Safety

By detecting defects or issues with PPE, the DEKI Computer vision System can help to ensure that workers are using safe and reliable equipment, reducing the risk of accidents and injuries.

Ease of Use

The DEKI Computer vision System is easy to set up and use, and requires minimal training to operate effectively. This allows for seamless integration into existing inspection processes and minimal disruption to day-to-day operations.

Scalability

The DEKI Computer vision System is scalable, meaning it can be easily integrated into existing inspection processes and expanded as needed to meet the changing needs of the business.

Our clients trust DEKI

Thank you for the excellent cooperation with DEKI. DEKI, though compact, is a modern, active, flexible, and highly efficient contractor for automation of PPE inspections with Computer Vision. I look forward to continue in the same manner on other projects."

David Michna

Senior specialist, WHS