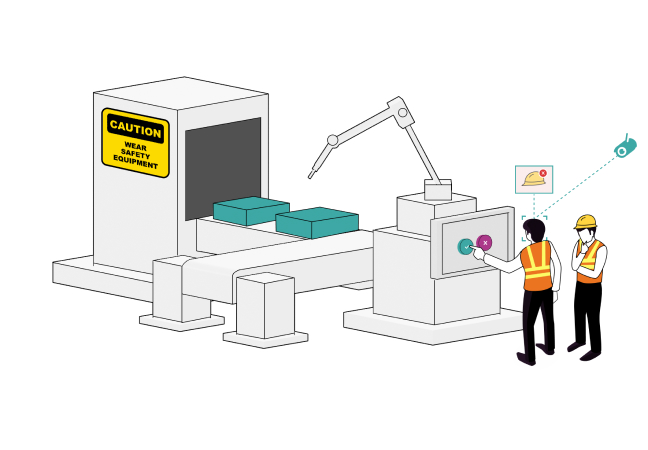

What is Automated PPE Inspection?

Computer Vision can be used to detect the presence of workers and equipment such as PPE (Personal Protective Equipment). Machine learning algorithms can accurately recognize objects at facilities and construction sites by analyzing real-time video streams from already installed IP camera surveillance systems. DEKI helps improve safety and productivity in manufacturing or construction, by detecting and monitoring PPE usage by helmet detection, eye protection detection, vest detection, and more.

24/7 With a High Accuracy

The automated equipment inspection works 24/7/356, is more consistent and generates more accurate results compared to the human inspectors.

Real-Time Notification

Get notified instantly any time there is a detected safety violation and follow up with an action: trigger audio announcements, stop machine operation to prevent injury and more.

Safety Report Creation

All of the data from detected events is stored locally on the premises and it can be used to create statistics and safety reports for upper management and insurance companies.

Key Features of PPE Detection

Real-time object detection for the inspection of PPE is an automated, scalable, and non-invasive solution to quickly improve workplace safety. Employers will find that implementing DEKI software also brings other benefits such as:

Prevent

workplace injuries

and illnesses

Improve

compliance with safety laws

and regulations

Detect

objects important

for your business

Save

costs, including workers

compensation premiums

Increase

productivity with automation

of business operations