The compliance of head-mounted industrial PPE by using deep learning object detectors

14 March 2023

A study published in Scientific Reports has shed new light on the importance of PPE inspection in our time. The ongoing technological progress has significantly increased the reliability of industrial equipment, leaving human factors as the leading cause of workplace accidents. Reports from the US alone indicate that injury costs were estimated at $161B, with an average annual cost of $1100 per worker (i.e., a factory of 1000 workers has an annual cost of $1.1M due to injuries and accidents). Occupational safety and health (OSH) is an interdisciplinary scientific field that aims to create a workplace environment that ensures employees' well-being, safety, and health at work. Together with employee education, the frontline OSH measure for preventing workplace injuries is the use of personal protective equipment (PPE), which is also regulated by corresponding standards and guidelines for each sector of the industry. However, the practice has shown that the misuse of PPE represents a serious issue for both companies and healthcare systems budgets (i.e., 360B dollars annually in the US alone), as well as employees facing the consequences of injuries. Finally, reports show that large portions of recorded injuries could be prevented through the proper use of PPE, and the affordability of PPE nowadays does not represent an obstacle to ensuring workplace safety.

Safety managers in most companies have limited capacity for timely and objective observation of large manufacturing halls and hundreds of employees or visitors circulating within workplaces. As an alternative, there is a growing need for computerized tools that can assist safety managers by indicating violations of prescribed protection measures.

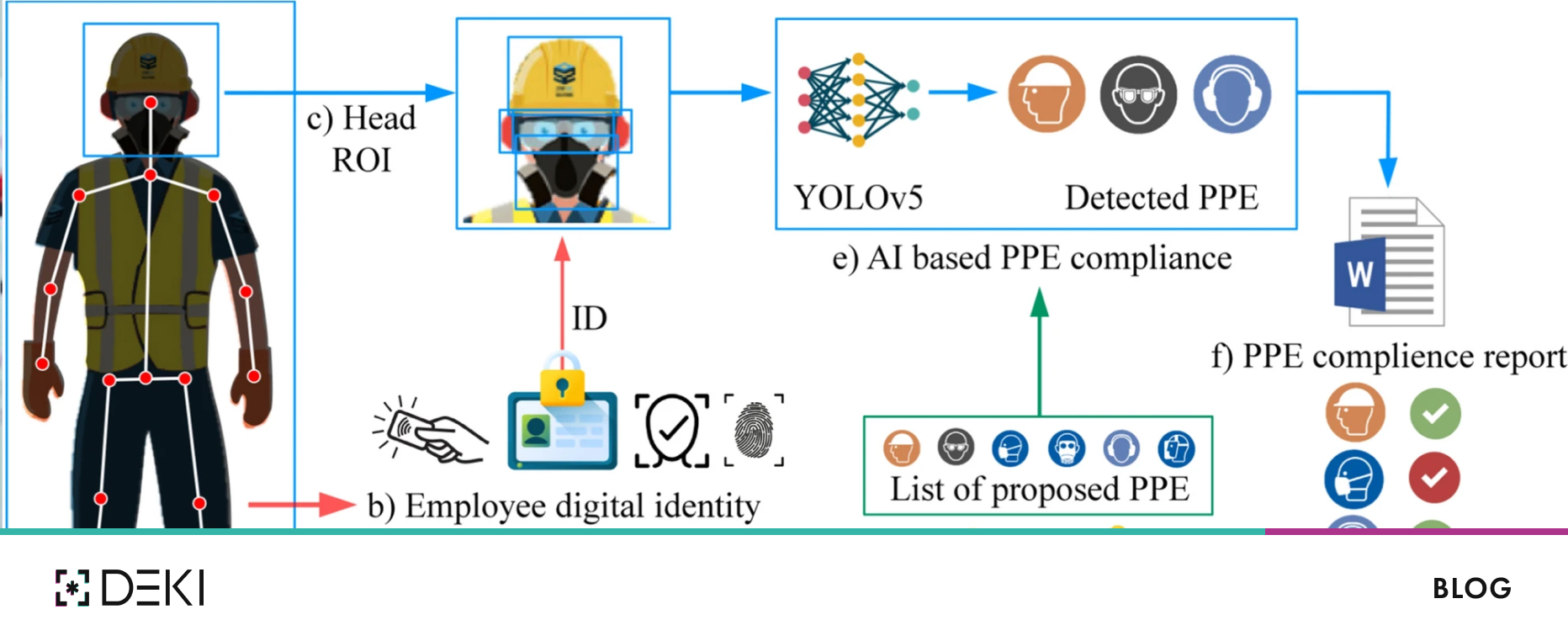

One such tool is the use of computer vision systems for PPE inspections. This technology uses cameras and artificial intelligence algorithms to detect whether workers are wearing the correct PPE, such as hard hats or safety goggles. This approach has been shown to be effective in improving PPE compliance and reducing workplace accidents. Compared to other methods, such as sensors on equipment or smart PPE compliance frameworks, computer vision systems offer a contactless and scalable solution for PPE inspections.

Source: Isailovic, V., Peulic, A., Djapan, M. et al. The compliance of head-mounted industrial PPE by using deep learning object detectors. Sci Rep 12, 16347 (2022). https://doi.org/10.1038/s41598-022-20282-9